Flat Fusion System

Our Flat Fusion System is a method of generating Joule heat with a heating element put inside the thermoplastics. (Patented)

The original ideas inspired by a wealth of experience and rich know-how in welding technology have made possible surface welding that boasts a stable seal with high finishing quality. It offers high added value, not only with its functionality, but also with excellent aesthetics.

Flat Fusion System features

- 1) The welding surface attains a stable seal

- 2) The welding surface is even

- 3) The lack of vibration protects inner parts from harm

- 4) The work environment can be improved (no noise, high temperature, or odor)

- 5) Complex shapes can be handled

- 6) The heating element (wire) can be easily separated by elecrtifying it again.

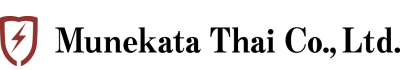

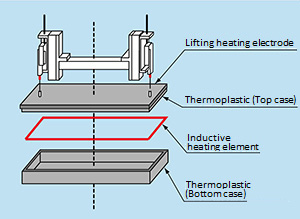

Flat Fusion System mechanism

The Flat Fusion System bonds plastic parts by sandwiching a heating element between the parts and electrifying the heating element to generate heat to soften the peripheral plastic and fuse it together. The plastic parts are then welded together with pressure.This creates a complete seal on the welding surface which prevents the problems that plagued eariler forms of welding.

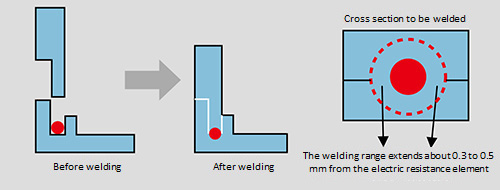

Flat Fusion System welding strength test

- Test object: FFS welding strength

- Device used: Tension tester

- Materials: ABS, wire (Φ0.9), wire length 30mm (A straight portion is cut at 30 mm)

- Test method: The strength is measured with the tension tester as the welding work piece is pulled.

| Work piece no. | Strength | Per 10mm |

| 1 | 445 | 148.3 |

| 2 | 475 | 158.3 |

| 3 | 364 | 121.3 |

| 4 | 335 | 111.7 |

| 5 | 387 | 129.0 |

| Average | 401.2 | 133.7 |

| Maximum | 475 | 158.3 |

| Minimum | 335 | 111.7 |

Welding strength measurement result (unit: N)

(Strength test speed 20mm/ min)

Shimadzu Autograph AG-1 series (floor type) used for measurement

※The data at left are examples based on our test results and are not guaranteed values.

In No.1 and 2, the base material broke before the welding area split.

Therefore, the welding strength peak is probably higher than the strength at which we stopped.